Manufacturers increasingly rely on technology to produce and distribute goods. Robotics play a key role in the manufacturing and assembly of products in factories. Sensors and beacons in Internet of things (IoT) devices track products as they progress along the supply chain and help monitor inventory in warehouses.

Manufacturers leverage artificial intelligence (AI) to make complex business decisions based on the latest information. Deloitte predicted that the AI market will reach $72 billion by 2021 as it is driven by manufacturing use cases, including customer service, quality assurance, fraud detection, and diagnostics.

As manufacturers come to depend on technology to do their work, disaster recovery for IT systems becomes crucial. If a natural disaster, an equipment failure, or a major breach hits a manufacturer, production would come to a grinding halt, leading to customer churn and major losses in revenue.

Cloud-based disaster recovery meets the unique challenges that manufacturers face when trying to maintain business continuity.

Here’s a look at 3 reasons why manufacturers should turn to the cloud for disaster recovery:

1) Geographic Diversity

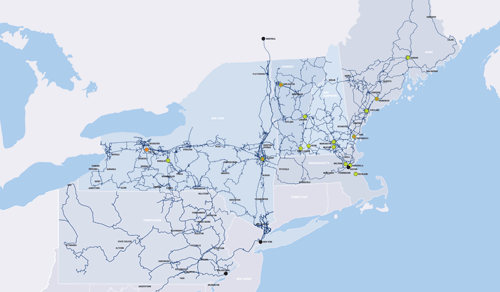

Manufacturers use geographically distributed assets, all of which are vulnerable. Warehouses and factories are located in separate areas. Having multiple facilities increases the odds that one could be knocked out by a fire, a flood, or an outage.

Manufacturers use geographically distributed assets, all of which are vulnerable. Warehouses and factories are located in separate areas. Having multiple facilities increases the odds that one could be knocked out by a fire, a flood, or an outage.

These locations also need to be able to communicate with each other to ensure that supply meets demand. Call centers and the main office receive orders that need to be fulfilled based on the status of the inventory.

Disaster recovery as a service (DRaaS) ensures that manufacturing businesses are better protected in the event of a traumatic incident. The right cloud provider will offer numerous geographically distributed cloud data centers. These off-site data centers provide backup and instant failover in the event of an outage at any location.

2) Customer Satisfaction

In manufacturing, customer and client satisfaction is everything. Some customers depend on your company for the equipment and products they need to do their jobs. Others rely on your goods to stock their shelves so they can serve their own customers.

To keep their customers happy, manufacturers need to guarantee business continuity. If production slows or shuts down, your clients will switch to your competitors.

Disaster recovery provides redundancies that prevent a single point of failure in your network infrastructure from interrupting the assembly line or supply chain. Instant failover can reduce recovery time objectives (RTOs) and ensure that you will be there to serve your customers when they need you.

3) Reliability of the Supply Chain

All the links in the manufacturer’s supply chain are located in different areas. If one link is broken, the whole chain fails. Trucks need to communicate with the factory and warehouse, as well as material suppliers and customers.

All the links in the manufacturer’s supply chain are located in different areas. If one link is broken, the whole chain fails. Trucks need to communicate with the factory and warehouse, as well as material suppliers and customers.

If communications break down, raw materials won’t get to the production facility in time. Factory workers can’t manufacture any new products without supplies. Eventually, inventory can run out, leaving customer orders unfilled.

DRaaS can protect a wide geographical area, ensuring that current data can be sent between manufacturing sites and trucks on the supply chain. When DRaaS is supported by a secure and reliable network, communications continue uninterrupted.

Disaster Recovery: The Key to Success

As the manufacturing industry continues to undergo a digital transformation, maintaining a robust disaster recovery plan will be vital to achieving success. DRaaS has the capabilities needed to keep manufacturers up and running after a crisis. Cloud-based disaster recovery ensures that manufacturers can also work with the accurate, current, and complete information they need to make crucial decisions.

FirstLight specializes in working with manufacturers to design technology and communications systems that meet the industry’s needs. We offer cloud-based disaster recovery supported by a reliable and secure fiber optic network that ensures all your locations and assets are connected. Our award-winning replication and recovery software eliminates costly downtime for your business.

Does your manufacturing company have adequate disaster recovery? Check out our solutions for manufacturers here. Let FirstLight help your manufacturing company connects with success.