Like most industries, high-tech manufacturing is undergoing a digital transformation. Data is influencing the way products are designed, produced, and distributed. Factories, warehouses, and supply chains are being transformed into smart spaces equipped with connected devices that generate valuable data.

As high-tech manufacturing processes undergo digitization, connectivity becomes more important. Data needs to be transmitted quickly and safely so crucial and profitable decisions can be made.

1) Visibility Into the Supply Chain

The supply chain can be tricky to track. Products need to be shipped around the country or even around the world. While vehicles are in transit, the main headquarters may have difficulty predicting when products or supplies will arrive. If a manufacturer can’t be sure of delivery times, it can’t be confident about filling orders or meeting production quotas.

The supply chain can be tricky to track. Products need to be shipped around the country or even around the world. While vehicles are in transit, the main headquarters may have difficulty predicting when products or supplies will arrive. If a manufacturer can’t be sure of delivery times, it can’t be confident about filling orders or meeting production quotas.

The location of cargo containers can be tracked using GPS and satellites. Tracking devices notify the manufacturer of the exact location of supplies in real time. The accuracy and timeliness of information are dependent on the speed of the network that transmits this information.

2) Accessing Data From IoT Devices

The internet of things (IoT) has become an integral part of every aspect of high-tech manufacturing. IDG’s 2018 State of Digital Business Transformation survey found that the manufacturing industry is a leader in the adoption of IoT.

Sensors on shipping containers allow the manufacturer to track shipments. In the factory, assembly line equipment is equipped with sensors that can detect any performance problems. Vehicle fleets are armed with sensors that can predict maintenance problems. Sensors can also be used to track inventory and streamline the picking process in the warehouse.

Connectivity enables manufacturers to transmit the data from these sensors. Many of these sensors may be in remote locations in the field, in the factory, or in a warehouse. This data needs to be transmitted quickly to company headquarters so it can be analyzed and applied to decision-making. A high-speed network makes it possible to use IoT data to improve processes and conduct proactive maintenance.

3) Communicating With Customers

Faster and more reliable communication with customers is essential to providing an exceptional customer experience. Customers want manufacturers to be available at any time to field questions, receive orders, and respond to complaints.

Faster and more reliable communication with customers is essential to providing an exceptional customer experience. Customers want manufacturers to be available at any time to field questions, receive orders, and respond to complaints.

Unified communications (UC) gives high-tech manufacturers many options for communicating with customers. Customers can reach out using voice, email, and instant messaging. With UC, voicemails can be converted into emails, and calls can be rerouted from a desk line to a mobile device. Manufacturers can also conduct face-to-face meetings with clients through web conferencing.

4) Collaborating With Product Developers

Getting new and innovative products to market quickly is key to profitability for high-tech manufacturers. Research and development requires collaboration between team members, who are often geographically scattered around the world. If these team members can’t communicate efficiently, work gets duplicated, mistakes happen, and time is wasted.

Connectivity opens the door for unified communications. With UC, members of a product development team can collaborate using a variety of tools. They can share documents and maintain version control so everyone is on the same page. The manufacturer can also share data concerning customer feedback and purchasing histories so products can be customized to meet demand.

5) Optimizing Asset Management

Manufacturers often need to keep their equipment running constantly to meet customer demand. To prevent downtime, manufacturers must take a preventative approach to maintenance rather than a reactive approach.

Manufacturers often need to keep their equipment running constantly to meet customer demand. To prevent downtime, manufacturers must take a preventative approach to maintenance rather than a reactive approach.

Keeping track of equipment life cycles and enabling proactive maintenance require that high-tech manufacturers use asset management software that collects data about equipment failures and potential vulnerabilities.

Company assets may be geographically distributed. To collect, transmit, and gain actionable analytics from asset management data, manufacturers need to use a high-speed network. Data must be transmitted quickly and securely, without being affected by bottlenecks or potential compromise.

Manufacture Smarter

High-speed connectivity enables high-tech manufacturers to take advantage of the benefits of smart factories, warehouses, and supply chains. Connected devices allow manufacturers to reduce risk, customize products, and cut costs. Management consultants McKinsey & Company identified operations optimization and predictive maintenance as two of the primary use cases for connectivity in manufacturing.

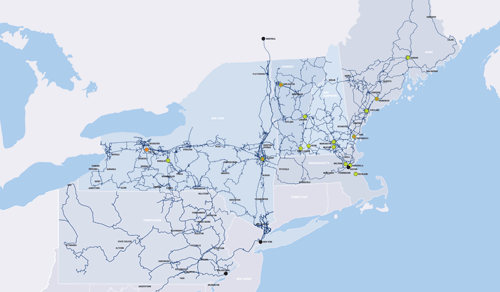

FirstLight is your source for leading connectivity solutions that support the manufacturing industry. We provide an extensive high-speed fiber optic network for manufacturers so data can travel quickly and safely from connected devices to be analyzed. Our voice and cloud solutions enable manufacturers to leverage unified communications for better collaboration and customer experiences.

Are you lacking the connectivity you need to be a smart manufacturer? Check out our solutions for manufacturers. Let FirstLight get you up to speed.