In this time of crisis, some manufacturers have stepped up, repurposing their assembly lines to make vital equipment, such as masks, ventilators, and face shields. Even before the pandemic, manufacturers provided essential resources for the community.

That’s why manufacturers should take advantage of the latest network technologies. A reliable, high-performance, and secure network ensures that manufacturers are operating optimally all day every day.

Switching from a traditional wide-area network (WAN) to a software-defined WAN (SD-WAN) can help manufacturers overcome networking and connectivity challenges to perform optimally after a crisis and when operations transition to the new normal.

Here’s a closer look at how SD-WAN helps manufacturers do their important work:

1) Improving connectivity

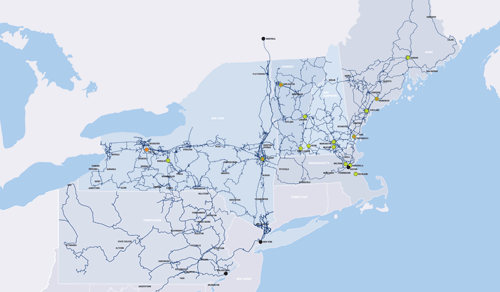

Connectivity is essential in manufacturing because multiple sites need to be in constant communication. A manufacturing business is comprised of geographically distributed locations, such as warehouses, factories, and branch offices. Manufacturers also need to be connected to suppliers and distributors so they can manage the supply chain.

SD-WAN can connect thousands or even tens-of-thousands of locations. The cloud-based solution can scale to meet increasing connectivity needs as a business grows. Management is easy, even when the network connects numerous locations. SD-WAN management is centralized through an orchestration engine that allocates network resources and balances workloads.

2) Enhancing network security

2) Enhancing network security

The 2019 Manufacturing & Distribution Report found that half the companies surveyed had experienced a breach in the past 12 months. Why are manufacturers such attractive targets for cybercriminals?

Manufacturers traffic in a currency that is just as valuable as, if not more than, money: intellectual property. A manufacturing company designs and assembles unique products. Hackers may want to steal the secrets behind what makes these products successful.

For this reason, manufacturers need to use a network that promotes security. The ideal SD-WAN solutions will provide a firewall, malware protection, and intrusion and detection services. A comprehensive approach to security will protect valuable company and customer data from attacks on the network.

3) Segmenting the network

Network segmentation is another way to increase security through SD-WAN. SD-WAN allows manufacturing companies to set policies for network segmentation. Access to data and applications can be controlled by user type, protecting assets in remote locations, in the data center, and everywhere in between.

Network segmentation is key in manufacturing because these businesses rely on multiple sites and numerous job roles. Segmentation gives line of business, quality control, warehouse, managerial, and supply chain users access to only the data and applications they need to do their jobs.

4) Optimizing IoT

4) Optimizing IoT

Manufacturers use the internet of things (IoT) on the factory floor, in the warehouse, and throughout the supply chain to ensure that equipment is operating optimally and inventory is meeting or exceeding demand.

The connected devices in IoT create additional complexity for the network. Each device is an endpoint that needs to communicate with the cloud or on-site data center. These endpoints also create vulnerabilities that need to be secured.

SD-WAN is software-based, so it decreases the complexity of the network while meeting the needs of IoT. Less hardware is needed to support the network. SD-WAN also provides visibility through a single pane of glass for centralized management and end-to-end protection of IoT assets.

5) Increasing flexibility

Manufacturers need to stay flexible to adapt with changes in the market. Increased product demands mean an extra strain on the network. The current crisis underscores how agile manufacturers must be. New product introduction has always been manufacturing’s bread and butter, but now some companies have needed to shift gears entirely.

Traditional WAN takes months to deploy, preventing manufacturers from adjusting their networks in a timely manner to meet new workload demands. Because it is software defined and cloud based, SD-WAN can be deployed in just hours.

SD-WAN for Manufacturing

Companies in the manufacturing industry have unique network requirements that can be met by SD-WAN. Partnering with a network provider that has experience working with manufacturers will ensure that your company gets what it needs out of an SD-WAN solution.

FirstLight specializes in working with manufacturers. We partner with Cisco to give our manufacturing clients access to leading SD-WAN solutions. We provide both SD-WAN Foundations and SD-WAN Advanced offerings to meet your company’s needs.

See how SD-WAN will work for your company. Request a FirstLight SD-WAN Demo and earn a $100 gift card.