The manufacturing industry is embracing cloud computing. According to the IDC FutureScape: Worldwide Manufacturing 2018 Predictions, by 2020, 75% of manufacturers will be using cloud models and services designed for the industry.

Why are manufacturers turning to the cloud?

Like businesses in other industries, manufacturers are undergoing a digital transformation. Manufacturers realize that the data generated by connected devices, customer interactions, and the supply chain is extremely valuable. However, for this value to be extracted from the data, it needs to be handled in the proper way.

The cloud provides a way for manufacturers to better store, access, and process data so they can make smarter and more profitable business decisions.

Here is an overview of 5 ways the cloud contributes to the success of manufacturers:

1) Supporting IoT

IDC predicted that by 2021, 20% of Global 2000 manufacturers will be using the Internet of Things (IoT) as part of an embedded intelligence system that will accelerate processes by 25%. Manufacturers use connected devices in factories to monitor equipment, in warehouses to control inventory, and in the supply chain to track and expedite shipments.

IDC predicted that by 2021, 20% of Global 2000 manufacturers will be using the Internet of Things (IoT) as part of an embedded intelligence system that will accelerate processes by 25%. Manufacturers use connected devices in factories to monitor equipment, in warehouses to control inventory, and in the supply chain to track and expedite shipments.

With the cloud, the data generated by these connected devices can be transmitted, stored, and processed. Because of its scalability, the cloud is ideal for storing the huge volumes of data created by IoT devices.

Data from hundreds of devices located across a wide geographical area can be collected and compiled in a centralized cloud database. By eliminating data silos, the cloud allows manufacturers to get a complete and accurate picture of their business information.

2) Enhancing Customer Service

IDC forecasted that 50% of manufacturers will be using customer feedback to develop new products, increasing the success rate of new product introductions by 25%. Customer feedback can be accessed through crowdsourcing, social media, and consumer interactions.

The cloud helps manufacturers collect customer data so it can be analyzed and applied to future interactions. Data on purchasing histories can be aggregated and analyzed to predict future behaviors and anticipate needs.

The cloud also provides a platform for ERP and CRM systems so customer orders can be compared with available inventory and tracked as they are shipped. Furthermore, cloud-based customer contact center solutions allow manufacturers to provide customers with voice activated menus for billing, ordering, and other options when they call a customer service line. All of this adds up to a personalized customer experience that encourages loyalty.

3) Allowing for secure interactions with suppliers

Supply chains create points of vulnerability for manufacturers. Terrorists and pirates may target supply chains for cyberattacks.

Supply chains create points of vulnerability for manufacturers. Terrorists and pirates may target supply chains for cyberattacks.

Risk analysts at the British Standards Institution reported that 40% of supply chain attacks target industrial and manufacturing materials.

For example, in 2017 a shipping container company suffered a ransomware attack that used the NotPetya virus.

Many cloud providers have enhanced security measures in place that become part of an overall solution to keep data secure. But of course, cloud data is just as much at risk and manufacturers should be prepared to recover quickly if ransomware strikes.

Cloud providers offer disaster recovery and backup to protect and preserve supply chain data when an outage or a breach occurs. With data protection in the cloud, all the links in your supply chain stay connected and available so your company can access real-time information about shipments and inventory.

4) Improving cost-efficiency

Moving manufacturing database resources to the cloud reduces capital expenses. Manufacturers avoid the costs of provisioning storage hardware. Instead they pay predictable monthly fees for the cloud resources they need.

When manufacturers use the cloud for IT infrastructure, they also save on data center real estate, energy, and cooling. The right cloud provider will deliver the latest technology and install any updates and refreshes that are needed without any additional investment from the customer.

5) Increasing Agility

In manufacturing, workloads can be unpredictable. Demands change with the whims of the customer base. For some manufacturers, workloads tend to spike seasonally and then fall off. Companies in the manufacturing industry need a way to provision more IT resources when needed, without leaving them idle during quieter times.

In manufacturing, workloads can be unpredictable. Demands change with the whims of the customer base. For some manufacturers, workloads tend to spike seasonally and then fall off. Companies in the manufacturing industry need a way to provision more IT resources when needed, without leaving them idle during quieter times.

The cloud allows manufacturers to scale up and down based on shifting demand. Additional cloud resources can be provisioned at will and paid for as needed. With cloud, your company can increase its agility without wasting money on resources that are only needed temporarily.

Cloud Offerings for Manufacturing

Today, every industry recognizes the value of cloud. However, cloud brings different advantages to each industry. Manufacturing companies need to find a provider that is familiar with the unique advantages cloud brings to them.

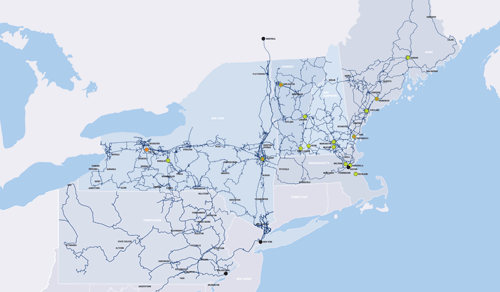

FirstLight has a long and successful track record of serving the manufacturing industry. We provide a full suite of cloud services to manufacturers, as well as voice, connectivity, and UC solutions. All our services are supported by an extensive high-speed fiber optic network that ensures optimal performance and reliability.

Take a deeper dive into FirstLight cloud offerings. Get your copy of our Cloud Computing fact sheet.