The manufacturing industry is undergoing a transition toward smart manufacturing. In smart manufacturing, business processes have become digitized. For example, companies rely on machine-to-machine communication through the internet of things (IoT) to make important decisions, maintain equipment, and monitor supply chains.

As manufacturers increasingly turn to IoT, robotization, and other innovative technologies, the cloud is becoming an essential part of the industry’s IT infrastructure. The cloud makes it easier and more cost effective for manufacturers to store, transmit, and protect mission-critical data.

The Digital Transformation of Manufacturing

Manufacturing companies face many challenges that are being overcome by technology. Workers and administrators need to communicate between the main office and remote locations in warehouses, in the field, and on the distribution route. Manufacturing processes need to be fast and efficient while maintaining consistently high quality. Companies need to track and maintain a variety of complex equipment.

IoT sensors enable manufacturers to collect data for predictive maintenance, supply-chain tracking, and inventory monitoring. Computer-aided design (CAD) and 3D printing streamline the process of designing and executing new products. Robotics ensure that products are assembled efficiently and properly.

All these innovations in the manufacturing industry produce data that can be analyzed to improve operations. The flood of data created by smart manufacturing introduces its own challenges. Manufacturing companies need to find better ways of handling this data so they can ensure its accuracy and accessibility. Correct business decisions need to be made with current and complete information from across the organization.

How Cloud Factors Into Manufacturing

According to the Information Technology & Innovation Foundation (ITIF), cloud computing is a vital part of the digital services that make up 25% of what goes into manufacturing a product. Cloud computing is the glue that holds everything together, enabling manufacturers to overcome information silos that keep different departments in the business from working in concert.

Instead of storing data in different departments, manufacturers can integrate all their databases in the cloud. Complex software such as ERP and CRM systems can be hosted on platform as a service (PaaS), enabling even small and medium-sized manufacturers to take advantage of enterprise-level resources.

As data volume increases from IoT devices or seasonal workload spikes, additional data center infrastructure can be provisioned in the cloud. Manufacturers pay a predictable monthly fee for the cloud resources they need to run their business and can easily scale back down when needed.

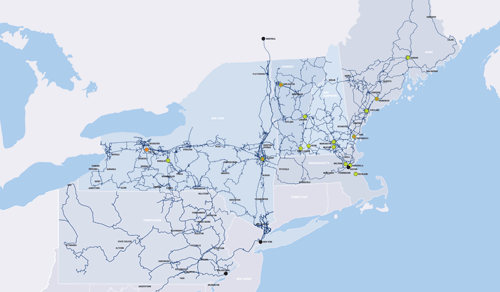

A cloud provider that uses a high-speed, fiber-based network enables companies to move data more quickly and reliably so they can take advantage of real-time data. Speed and reliability is key because manufacturers need to transmit data from geographically distributed IoT devices so it can be collected for analysis.

Protecting Data With Cloud

Using accurate and complete data is important to manufacturers. They need accurate data not only to make correct business decisions but also to ensure that they consistently produce a product of high quality. If equipment isn’t sending or receiving the right information, it may break down or produce a defective product which could ruin the company’s reputation and put consumers at risk.

The cloud provides the ideal environment to back up valuable data. Data can be stored off-premises so it stays safe after a natural disaster, data breach, or equipment failure. The on-site data center can be synced to the cloud to achieve instant failover.

Taking Manufacturing to the Cloud Brings Results

Adopting the cloud has proven advantageous for manufacturers. In the 2017 Propel Manufacturing Cloud Survey, 72% of respondents said that the cloud increased their productivity, and 60% reported that the cloud improved their agility. A manufacturing company that has undergone digital transformation but hasn’t yet moved to the cloud is missing an important piece of the puzzle.

Working with FirstLight will prevent your business from missing out on the benefits that the cloud brings to manufacturers. The cloud experts at FirstLight will help you make a smooth migration to the cloud. Our cloud solutions, paired with our high speed, fiber-based solutions, enable you to retain control over your mission-critical data while enjoying the advantages of the cloud.

FirstLight offers a range of cloud services and models, all connected to our secure, high-speed, low-latency fiber optic network.

Find out more about how the cloud can improve your business. Contact the cloud experts at FirstLight.